Wilderness

Experience

Chatsworth,CA

| |

| HOME |

| About Tenaya |

| About Us |

| Latest Update |

| Logs from Current Year |

| Logs from Previous Years |

| Katie's View |

| Route Map |

| Links |

| Contact Us |

![]()

FOR MORE INFORMATION: wildernessexperience.net

Bob’s Wilderness Experience

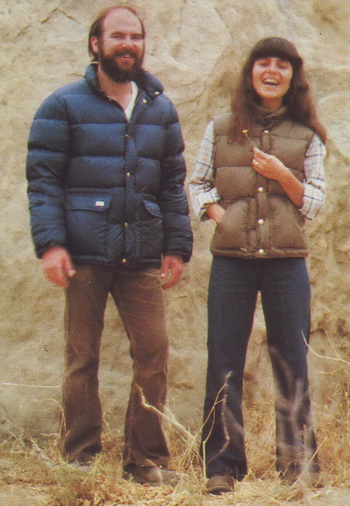

Bob and Nilli Rudolf

Bob’s Wilderness Experience

My experiences with WX span back years and my memory is not flawless, therefore, I will state that while my intention is to make an accurate reportage, it certainly contains errors of commission and omission. It covers a 5-year segment as seen from my perspective. The history of WX extends before and after my direct involvement and there are many other points of view.

Bob Rudolf, 2010

bobcrudolf@yahoo,com

It was spring, 1976. I scanned the want ads anxiously. Suddenly, the job that would become my career grabbed my attention. “BACKPACK ASSEMBLER NEEDED”. Gear freaks like me greatly respected Wilderness Experience, affectionately known to us as WX, Wild X, Wildy, or just Wilderness. Coincidentally, I had carried a (borrowed) WX Alpinist on my most recent trip to Europe and the Middle East in 1974-75. Not only did I need a job, I earnestly wanted to work for this company!

My future Supervisor and good friend, Peater Wilkening, conducted the interview. Peater, a “natural supervisor”, and a skilled Stony Point boulderer was among the most dexterous people, I had ever met. I tried like hell to beat him at the various assembly job challenges, but I never could! Occasionally, he would let me in on one of his profound assembly secrets, like predetermining the orientation of a split ring by its reflection on the workbench…as he reached for it. Peater taught me to use observation and imagination to find innovative new techniques.

After my first few months, we moved the factory from Winnetka Ave. a hundred yards or so northwest to a brand new and much larger site on Plummer St. and WE did move it! With the spirit and enthusiasm of a college football game, we tackled this project. Our whole team exerted extreme effort to make the move quickly. I had never witnessed anything like that! In hindsight, this was my first significant observation of Jim and Greg’s ability to lead people and inspire action.

Once we were in the new facility a short time, Diane Desmond, our Production Manager asked if I would transfer to the Cutting Department. Although I really liked my new position as Frame Pack Assembly Foreman, I discussed it with Peater, recognized this as a learning opportunity, and accepted the offer. Ginny Heitzmann, the newly appointed Cutting Supervisor, taught me what was required in order to produce quality parts. At that time, only Jim, Greg, and Ginny (in the entire company of about 100) knew anything about cutting pack fabrics.

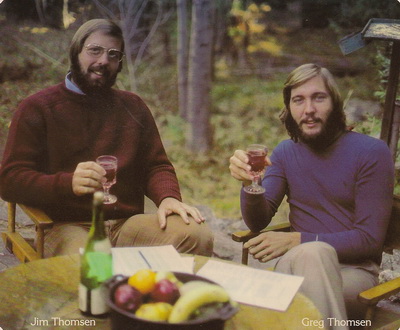

I will digress at this point to acknowledge the young visionaries I witnessed contribute to the early achievements of this great company and to my own personal growth and development toward the modest degree of success, I have enjoyed in the outdoor equipment industry. Jim and Greg Thomsen, the “First Cause”, the “Prime Movers” of Wilderness Experience were the dynamic and charming believers in our ability to do what was required to be successful. This phenomenal company could not have occurred without their vision and unbound energy. Diane Desmond, our Production Manager, and future Vice President of Manufacturing, worked more intensely than anyone and inspired us all. The aforementioned Peater Wilkening, after leaving his positive influence on many at WX, went on to facilitate Gramicci’s growth into major industry force and now, has been a production manager with Black Diamond for many years. Ginny Heitzmann, who honed her skills to become one of the most efficient cutters I have known, is principal of Gold Coast Garment Cutting in Ventura, CA with clients such as Gramicci and Patagonia. Others, who were instrumental in our success at that time, include Bonnie Campbell, Debbie Desmond, Dana Johnson, Linda Lockwood, Susan Miller, and Eric Schall. My apologies if I inadvertently omitted other significant contributors or for any misspellings.

It was perhaps the fall of 1976. Sales were doubling annually and to say the company was experiencing growing pains would be a gross understatement. The systems that functioned fine in the beginning were now inadequate and slowing us down. We overcame these handicaps through shear effort and determination. At this point, I had a major epiphany, if I could help to find solutions that would eliminate or at least mitigate these handicaps, I might gain advancement and job security in this exquisitely unique organization….

In January of 1977, Peater and I attended the WAM SHOW (Western Apparel Magazine) at the Los Angeles Convention Center. There, while observing CAD marker making software, I received my first insight into increasing fabric utilization through efficient nesting and interlocking of parts. (A marker is a sheet of paper with tracings of the various pattern pieces in the correct proportions to make the required quantity of finished product per ply of fabric. Then, it is affixed to the top of the lay [stack of fabric] as guide for the cutting machine operator). Upon returning to work, I redrew our standard Book Pack marker employing the new principles I had observed, and to my delight, it was by 12% shorter. I waited for the opportunity to show it to Jim and when it came, I unrolled my marker on top our standard marker, which was a full yard longer. Evidently it made a positive impression because soon thereafter, Diane informed me that Jim and Greg wanted me to become the “plant efficiency expert” and my first assignment, after I returned from a 3-day New York University seminar at a San Francisco hotel, was to establish piecework in Assembly. I had never attended a business seminar, nor been given that degree of creative responsibility. I was ecstatic…but totally terrified!

In addition to the formal skills acquired in those three days, the seminar increased my insight and enhanced my confidence. I also learned that that the proper title of my new position was “Industrial Engineer”. One evening after the seminar had concluded for the day, Jim and Greg picked me up and took me to dinner at a luxurious restaurant in Downtown San Francisco. There, the three of us sat down with two Vice Presidents of Celanese Corp, the makers of PolarGuard. (After the demise of Snow Lion, we were making sleeping bags at a contractor in South San Francisco and consuming large quantities of the insulation). During the ensuing conversation, it became obvious that Jim and Greg were at least as capable as those corporate leaders sitting across the dinner table. My favorite highlight occurred when the “veeps” tried to rationalize a price hike by citing increases in material and operating expenses and the ever-quick-witted Greg responded curtly, “It’s remarkable the management of a major corporation like yours, can’t control its manufacturing costs.” (!)

I returned to Chatsworth with my mind churning. Flow charting, work simplification, design consolidation, motivational psychology, and more. Although I learned, corporate executives and other industrial leaders need not intimidate me; I was not sure how my former peers would accept my new role. Moreover, ironically the seminar did little to address how to establish the wage incentive (piecework) system, which was my assignment. However, I was beginning to comprehend that there was much more to increasing productivity than wage incentives.

I understood that to be effective in my new role, I needed to first gain the respect of my former peers. A way to accomplish that, I thought, would be to conceive of ways to make their jobs easier. My first idea, in Frame Pack Assembly, was to install fixtures in order to secure and stabilize the pack frames during the tensioning of the mesh back bands and hip belts. I concurrently installed foam between the operators and the workbench to cushion the pressure on their hipbones. Prior to this we “pulled” the mesh and webbing by resting the frame against our bellies. It was right then, I first learned that people naturally resist change. “Why was this necessary”? However, before long, rock climber and friend, Jim Wilson, the new Foreman, reported it reduced fatigue and helped speed the process. That was gratifying!

My first business card read “Bob Rudolf, Research, and Development”; I was totally stoked! I submitted changes in design to Greg that I reckoned would save labor and materials, increase quality or both. We collaborated on a new frame pack hip belt that was a major improvement in comfort, carry, and adjustability while simultaneously improving production efficiency. It was featured in a 2/3 page ad in the December 1977 issue of Backpacker Magazine with a photo of Greg and I. On top of that, Greg honored me with the task of writing the copy. It was the thrill of my life to have my photograph and story appear in a national publication. Jim and Greg knew how to motivate me!

The very first experimental garments, I recall we made were plaid wool shirts and cotton/poly hiking shorts. I drew up the marker for a size-run of shirts, and then, Greg and I stayed late and spread the coarse wool blend on the cutting table. It was a hilarious near-disaster. We had no spreading machine and had no idea how to use one anyway. The first ply was no problem, but to avoid disturbing the lay as we dragged each new ply across it, required innovation….We stationed ourselves on each side of the long cutting table and lifted the ends of the fabric high over our head. We then ran the 25’ length of the marker, carefully keeping a cushion of air between that ply and the lay. After laying up the goods, we left feeling that we had accomplished the task, but upon arriving the next morning, I was shocked to discover that the 25’ lay has shrunk to 23’! We instantly learned that dimensionally unstable fabrics, spread under tension tend to contract. Fortunately, I was able to redraw the marker and it worked out. The lesson was that we had better learn how to use a spreading machine! To my knowledge, these first two experiments yielded no marketable first quality garments, but we all wore them anyway.

As time passed, I continued my “education” by reading everything I could get my hands on, attending numerous classes and seminars, visiting the manufacturing facilities of other sewing companies, and cutting services in and out of the backpacking industry and asking many questions. In the course of the next year, we established wage incentives in assembly, improved the incentives and productivity of our sewing operations and much more, we even learned how to use a spreading machine.

My next hike on the Wilderness trail was to be appointed Production Manager of our new Insulated Products Division at our satellite plant located in North Hollywood, about 12 miles east of the main Chatsworth factory. When we abandoned the sleeping bag contractor in South San Francisco, we began producing all our PolarGuard sleeping bags and our new outerwear in North Hollywood. At that time, I started developing new sewing methods to increase the loft of our bags compared with traditional “sandwich” techniques. When writing the catalog copy, I dubbed this original design the “Tri-Channel Baffle system”. We also developed and manufactured the first extreme Gore-Tex Gear, The Latok I sleeping bag, and The Blue Max parka (inspired by Jim Donini and Bev Johnson respectively). One can see Greg modeling The Blue Max, sporting black eyes and a broken nose in the ’77 catalog and on the WX website.

In 1978, we consolidated total production at our brand new 75,000 sq. ft. facility on Nordhoff St. in Chatsworth. Diane was promoted to Vice President of Manufacturing and I became the Plant Manager. Although we had been experimenting with down for the last year, our filling equipment was rather primitive and production was limited. Diane and I flew to Denver in order to view the operation of a state of the art, microcomputer controlled down filling machine (the PC had not yet been invented). We were very impressed. Whereas the equipment we had (York) would take at least ½ hour to fill a sleeping bag, this new machine (Clark) could accomplish the same task in less than 4 minutes with vastly improved consistency and flexibility! Jim and Greg purchased the machine on our recommendation. It was very expensive, but before long, we were producing down sleeping bags and outerwear in abundance.

Over the last couple of years, with Jim and Greg blazing the trail, we had transitioned from “Backpack Specialists” to a “Full-Line” company. Our four divisions: Packs, Tents, Sleeping Bags, and Outerwear* (including some of the first seam-sealed Gore-Tex shell garments) filled the new plant as sales continued to grow. I am privileged and awed to have had the opportunity to participate and contribute.

For me, in addition to our ambition to be a successful enterprise, producing quality gear, our most important attribute was that we made it exceedingly enjoyable. This attitude originated from Jim and Greg and permeated the entire company. However, after we went public, the internal complexion of the company changed. For reasons I have yet to comprehend completely, we were no longer having fun. Within a year or two of the IPO, many of us, including Eric, Ginny, Peater, I and eventually, Jim too, left the company.

Jim and Greg Thomsen launched a magnificent company, but they did much more, they launched lifelong careers. Peater, Ginny, Diane, Eric, and many others, owe our professional lives to founders of Wilderness Experience.

A personal epilog:

The lessons learned at Wilderness Experience, stayed with me and were applied and expanded upon at Gramicci, Summit Manufacturing (founded by Jim and I to make sleeping bags for WX), Adventure 16, Gregory Mountain Products, Osprey Packs and other companies in and outside of the outdoor industry.

BR

*I still frequently wear my WX Tuolumne Vest and Wind River and Storm Coat Gore-Tex shells. My WX Half Dome tent lived until 2007.

![]()

.